eidos

The new reference in heavy gauge vacuum forming

Style and performance in a new product that re-confirms CMS as market benchmark for heavy gauge vacuum forming. The new EIDOS encompasses sophisticated mechanical solution to guarantee the best performance on the market and a highly innovative, new software, for total machine control that is extremely easy to use.

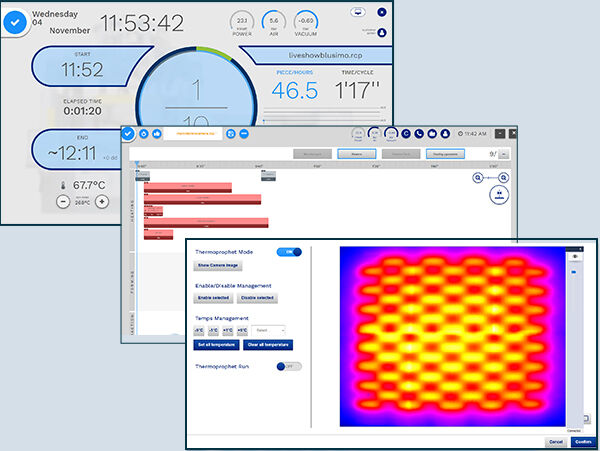

- New CMS HMI ThermoActive software designed specifically for the thermoforming process. The timeline and exclusive Dashboard make supervising production and the process control instant and easily understandable.

- CMS ThermoProphet system for the automatic management of the heating powers via thermal vision.

- The frame and counter mould movement with 4 electrically coupled Brushless motors (gantry). Transmission occurs via fixed toothed columns, eliminating moving mechanical parts that protrude from of the machine.

- New cooling system moulds with mobile outlets installed on the counter mould structure.

- Rapid format change thanks to fully automatic window plate and clamping frame.

- Mould table with PC controlled Brushless movement and with storable speed and measurements. The patented movement is achieved thanks to two electronically coupled servomotors (gantry), which guarantee the rapid and exact positioning of the mould.

Eidos comes in mono-station version as well as with automatic loading/unloading system in different configurations.

Technical data

| Model | Max sheet size | Mould | ||

| Max height | Max size | Max force | ||

| (mm) | (mm) | (mm) | (DaN) | |

| Eidos 1280 | 1260 x 860 | 450 | 1200 x 800 | 2000 |

| Eidos 1510 | 1560 x 1060 |

600

|

1500 x 1000 | 2000 |

| Eidos 1512 | 1560 x 1260 | 600 | 1500 x 1200 | 2000 |

| Eidos 2015 | 2060 x 1560 | 800 | 2000 x 1500 | 3900 |

| Eidos 2515 | 2560 x 1560 | 800 | 2500 x 1500 | 6100 |

| Eidos 2520 | 2560 x 2060 | 800 | 2500 x 2000 | 7500 |

| Eidos 3020 | 3060 x 2060 | 1000 | 3000 x 2000 | 10800 |

| Eidos 3525 | 3560 x 2560 | 1000 | 3500 x 2500 | 13500 |

Advantages

MAXIMUM CONTROL

Thanks to CMS ThermoActive, the thermoforming process parameter setting is immediate. A guided system makes the likelihood of error almost impossible, instantly highlighting errors and inconsistencies. The visual representation of the cycle provides clarity and immediateness to the software with learning times reduced by up to 53% (*). With CMS ThermoProphet (**) maximum heating stability can be guaranteed even in the presence of variables outside the thermoforming machine. Maximum quality from the first piece produced! (*) compared to previous solutions (**) optional

SPEED AND ACCURACY

The sophisticated mechanical solutions allow for rapid movements combined with a completely new structural rigidity. The alignment of the new frame ensures excellent locking of the plate thanks to 4 motors. The new counter mould ensures doubled thrust levels (*) and an increased mechanical stability of 151% (*). The total absence of mobile transmission parts guarantees the reduction of the machine's overall height by up to 25% (*) while ensuring full control of the mould's maximum height, with or without loader and with both positive and negative moulds. (*) compared to previous solutions

OPTIMISED PROCESS

The new mould cooling system with "tilting" function reduces cooling times for the mould by up to 31% (*). The distance of the outlets from the piece and the width of oscillation can be programmed and stored in the recipe. The heating system with oscillating function guarantees maximum efficiency close to the clamping frame. The continuous power can be modified in order to better adapt the heating cycle according to the thickness of the plate, to achieve top quality with shortest heating cycle times and minimum energy consumption. (*) compared to previous solutions

FAST FORMAT CHANGE

The production change times are extremely fast, thanks to the mould table that can be removed using a trolley with pneumatic tool lifting system (**). A second kit (**) allows for the reduction of 75% in mould installation time allowing for set up without stopping production. EIDOS is, therefore, the ideal solution even for single batch productions. (**) optional

Dotaz na zboží

Videa

Videa Katalogy

Katalogy